Exploring the Advantages of Skived Heat Sinks in Thermal Management

Exploring the Advantages of Skived Heat Sinks in Thermal Management

Blog Article

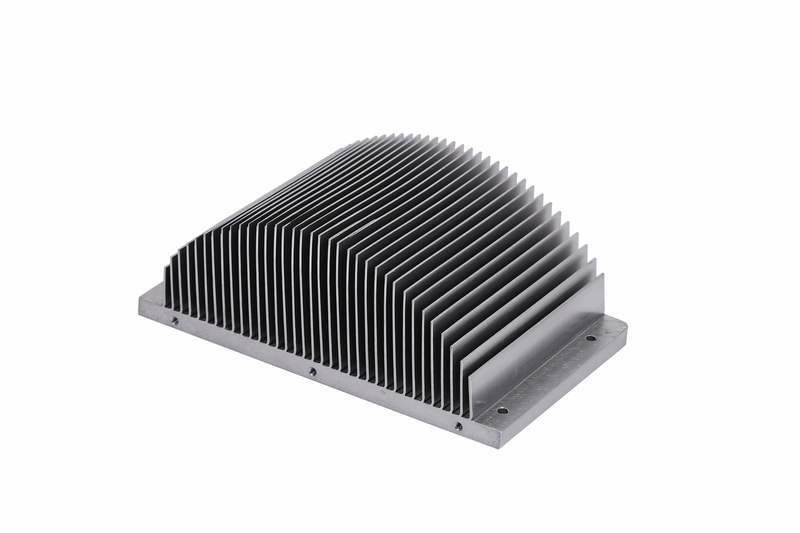

Efficient thermal management is a critical factor in the performance and reliability of modern electronics. One innovative solution is the best skived heat sink, a design that combines precision and high performance to dissipate heat effectively. Skived heat sinks are gaining popularity in applications that demand robust cooling solutions due to their unique manufacturing process and superior thermal properties.

What Are Skived Heat Sinks?

Skived heat sinks are created by cutting thin, continuous fins from a single block of metal—typically copper or aluminium—using a specialized blade. This manufacturing method produces a heat sink with a seamless connection between the base and the fins, ensuring optimal thermal conductivity. Unlike bonded or soldered heat sinks, skived heat sinks offer improved durability and consistent performance.

Advantages of Skived Heat Sinks

1. Superior Thermal Performance

The seamless construction of skived heat sinks eliminates thermal resistance between the base and fins, resulting in exceptional heat transfer. This makes them ideal for cooling high-power devices such as CPUs, GPUs, and power electronics.

2. High Fin Density

The skiving process allows for the creation of closely spaced, thin fins, which maximizes the surface area for heat dissipation. This increased surface area enhances the heat sink's ability to transfer heat efficiently to the surrounding air.

3. Lightweight and Compact Design

Despite their high performance, skived heat sinks can be designed to be lightweight and compact, making them suitable for applications where space and weight are constraints, such as in portable devices or compact industrial equipment.

4. Customizability

The skiving process offers significant flexibility in terms of design. Manufacturers can create fins of varying heights, angles, and densities to match specific thermal requirements. This makes skived heat sinks versatile for a wide range of industries and applications.

5. Improved Durability

Because skived heat sinks are made from a single block of metal, they are more durable and resistant to mechanical stress compared to bonded or soldered alternatives. This ensures long-term reliability, even in demanding operating environments.

6. Cost-Effective for High-Performance Applications

While skived heat sinks may initially cost more than simpler designs, their efficiency and reliability can lead to cost savings over time by reducing energy consumption, maintenance needs, and potential equipment failures.

Applications of Skived Heat Sinks

Skived heat sinks are used in various industries and applications, including:

Electronics: Cooling processors, graphic cards, and memory modules.

Telecommunications: Managing heat in network servers and base stations.

Automotive: Thermal management for electric vehicles and power inverters.

Industrial Machinery: Ensuring thermal stability in heavy-duty systems.

LED Lighting: Dissipating heat in high-output lighting solutions.

Factors to Consider When Choosing Skived Heat Sinks

To ensure you select the best skived heat sink for your needs, keep the following factors in mind:

Material Selection: Copper offers superior thermal conductivity, while aluminium provides a lighter, more cost-effective solution.

Fin Design: Choose a fin arrangement that balances performance with airflow requirements.

Application Requirements: Consider the power output and environmental conditions of your device to determine the appropriate heat sink design.

Manufacturing Quality: Ensure the heat sink is crafted with precision to guarantee consistent performance.

Customization Options: Look for manufacturers that can tailor the design to meet your specific thermal management challenges.

The best skived heat sink offers unmatched thermal performance, durability, and design flexibility, making it an ideal choice for advanced cooling applications. By leveraging the advantages of this innovative technology, industries can enhance device performance, ensure reliability, and meet the growing demands of modern thermal management challenges. With its combination of efficiency and precision, the skived heat sink stands out as a vital component in the world of high-performance cooling solutions.